Project Background

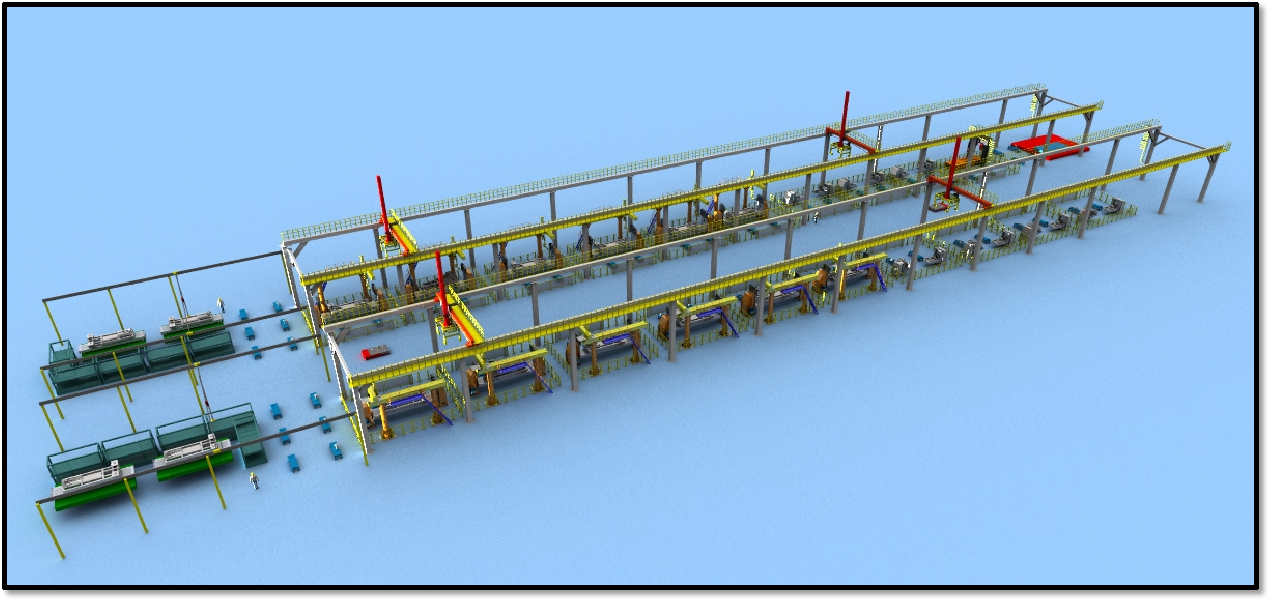

Project Background In this project, Party A needs to use a robot to realize automatic gripping and handling of steel plates after laser cutting.

The robot is required to have vision functions to recognize and locate the cut products and guide the robot's movements.

The robot needs to be a Cartesian Coordinate Robot (Truss Robot) with large load capacity and long stroke.

Dual grippers are required, capable of single gripper movement or dual gripper cooperative handling of large-sized products.

Home

Home