Project background

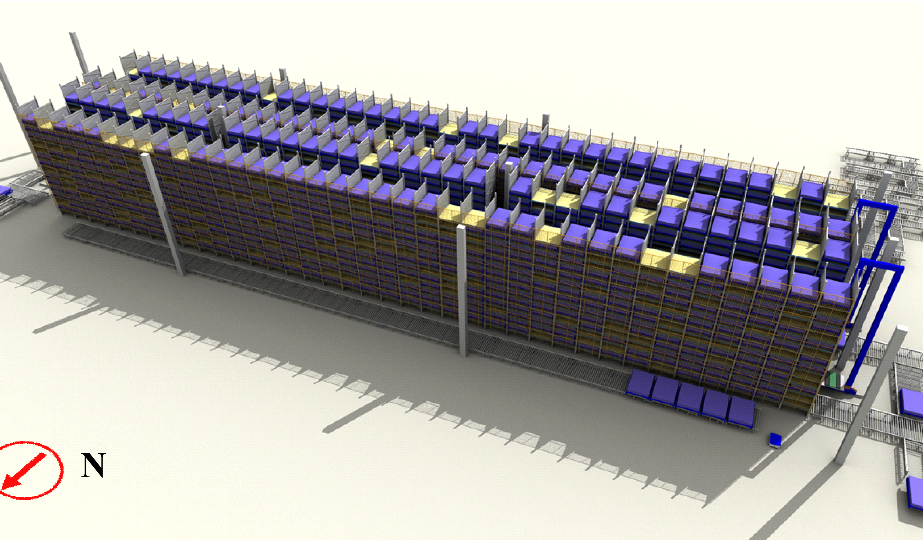

Project background This project aims to achieve the automatic connection between the production process and the upstream and downstream automation equipment to achieve fully automated management. The project covers rack pallets, stacker systems, conveyor systems, and computer management and scheduling systems.

Huibo Robot is mainly responsible for the design, production, procurement, transportation, installation and commissioning of the equipment required for the project. Using 2-aisle stackers for stereoscopic warehousing, it can carry a load of 1T and has more than 2,000 storage locations. The height of the stereoscopic warehouse is 11.5 meters. Through conveyor lines, AGV and other equipment, it can be docked for inbound and outbound.

Each product will be dispatched after being stored for 2 days of self-discharge, and the overall circulation adopts the method of right-in-left-out and first-in-first-out. The implementation of this project will realize the automated management of the production process and improve production efficiency and management level.

Home

Home